|

| November 05, 2019 | Volume 15 Issue 42 |

Motion Control News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Overhung load adaptors provide load support and contamination protection

Overhung load adaptors (OHLA) provide both overhung radial and axial load support to protect electrified mobile equipment motors from heavy application loads, extending the lifetime of the motor and alleviating the cost of downtime both from maintenance costs and loss of production. They seal out dirt, grime, and other contaminants too. Zero-Max OHLAs are available in an extensive offering of standard models (including Extra-Duty options) for typical applications or customized designs.

Overhung load adaptors (OHLA) provide both overhung radial and axial load support to protect electrified mobile equipment motors from heavy application loads, extending the lifetime of the motor and alleviating the cost of downtime both from maintenance costs and loss of production. They seal out dirt, grime, and other contaminants too. Zero-Max OHLAs are available in an extensive offering of standard models (including Extra-Duty options) for typical applications or customized designs.

Learn more.

Why choose electric for linear actuators?

Tolomatic has been delivering a new type of linear motion technology that is giving hydraulics a run for its money. Learn the benefits of electric linear motion systems, the iceberg principle showing total cost of ownership, critical parameters of sizing, and conversion tips.

Tolomatic has been delivering a new type of linear motion technology that is giving hydraulics a run for its money. Learn the benefits of electric linear motion systems, the iceberg principle showing total cost of ownership, critical parameters of sizing, and conversion tips.

Get this informative e-book. (No registration required)

New AC hypoid inverter-duty gearmotors

Bodine Electric Company introduces 12 new AC inverter-duty hypoid hollow shaft gearmotors. These type 42R-25H2 and 42R-30H3 drives combine an all-new AC inverter-duty, 230/460-VAC motor with two hypoid gearheads. When used with an AC inverter (VFD) control, these units deliver maintenance-free and reliable high-torque output. They are ideal for conveyors, gates, packaging, and other industrial automation equipment that demands both high torque and low power consumption from the driving gearmotor.

Bodine Electric Company introduces 12 new AC inverter-duty hypoid hollow shaft gearmotors. These type 42R-25H2 and 42R-30H3 drives combine an all-new AC inverter-duty, 230/460-VAC motor with two hypoid gearheads. When used with an AC inverter (VFD) control, these units deliver maintenance-free and reliable high-torque output. They are ideal for conveyors, gates, packaging, and other industrial automation equipment that demands both high torque and low power consumption from the driving gearmotor.

Learn more.

Next-gen warehouse automation: Siemens, Universal Robots, and Zivid partner up

Universal Robots, Siemens, and Zivid have created a new solution combining UR's cobot arms with Siemens' SIMATIC Robot Pick AI software and Zivid's 3D sensors to create a deep-learning picking solution for warehouse automation and intra-logistics fulfillment. It works regardless of object shape, size, opacity, or transparency and is a significant leap in solving the complex challenges faced by the logistics and e-commerce sectors.

Universal Robots, Siemens, and Zivid have created a new solution combining UR's cobot arms with Siemens' SIMATIC Robot Pick AI software and Zivid's 3D sensors to create a deep-learning picking solution for warehouse automation and intra-logistics fulfillment. It works regardless of object shape, size, opacity, or transparency and is a significant leap in solving the complex challenges faced by the logistics and e-commerce sectors.

Read the full article.

Innovative DuoDrive gear and motor unit is UL/CSA certified

The DuoDrive integrated gear unit and motor from NORD DRIVE-SYSTEMS is a compact, high-efficiency

solution engineered for users in the fields of intralogistics, pharmaceutical, and the food and beverage industries. This drive combines a IE5+ synchronous motor and single-stage helical gear unit into one compact housing with a smooth, easy-to-clean surface. It has a system efficiency up to 92% and is available in two case sizes with a power range of 0.5 to 4.0 hp.

The DuoDrive integrated gear unit and motor from NORD DRIVE-SYSTEMS is a compact, high-efficiency

solution engineered for users in the fields of intralogistics, pharmaceutical, and the food and beverage industries. This drive combines a IE5+ synchronous motor and single-stage helical gear unit into one compact housing with a smooth, easy-to-clean surface. It has a system efficiency up to 92% and is available in two case sizes with a power range of 0.5 to 4.0 hp.

Learn more.

BLDC flat motor with high output torque and speed reduction

Portescap's 60ECF brushless DC slotted flat motor is the newest frame size to join its flat motor portfolio. This 60-mm BLDC motor features a 38.2-mm body length and an outer-rotor slotted configuration with an open-body design, allowing it to deliver improved heat management in a compact package. Combined with Portescap gearheads, it delivers extremely high output torque and speed reduction. Available in both sensored and sensorless options. A great choice for applications such as electric grippers and exoskeletons, eVTOLs, and surgical robots.

Portescap's 60ECF brushless DC slotted flat motor is the newest frame size to join its flat motor portfolio. This 60-mm BLDC motor features a 38.2-mm body length and an outer-rotor slotted configuration with an open-body design, allowing it to deliver improved heat management in a compact package. Combined with Portescap gearheads, it delivers extremely high output torque and speed reduction. Available in both sensored and sensorless options. A great choice for applications such as electric grippers and exoskeletons, eVTOLs, and surgical robots.

Learn more and view all the specs.

Application story: Complete gearbox and coupling assembly for actuator system

Learn how GAM engineers not only sized and selected the appropriate gear reducers and couplings required to drive two ball screws in unison using a single motor, but how they also designed the mounting adapters necessary to complete the system. One-stop shopping eliminated unnecessary components and resulted in a 15% reduction in system cost.

Learn how GAM engineers not only sized and selected the appropriate gear reducers and couplings required to drive two ball screws in unison using a single motor, but how they also designed the mounting adapters necessary to complete the system. One-stop shopping eliminated unnecessary components and resulted in a 15% reduction in system cost.

Read this informative GAM blog.

Next-gen motor for pump and fan applications

The next evolution of the award-winning Aircore EC motor from Infinitum is a high-efficiency system designed to power commercial and industrial applications such as HVAC fans, pumps, and data centers with less energy consumption, reduced emissions, and reduced waste. It features an integrated variable frequency drive and delivers upward of 93% system efficiency, as well as class-leading power and torque density in a low-footprint package that is 20% lighter than the previous version. Four sizes available.

The next evolution of the award-winning Aircore EC motor from Infinitum is a high-efficiency system designed to power commercial and industrial applications such as HVAC fans, pumps, and data centers with less energy consumption, reduced emissions, and reduced waste. It features an integrated variable frequency drive and delivers upward of 93% system efficiency, as well as class-leading power and torque density in a low-footprint package that is 20% lighter than the previous version. Four sizes available.

Learn more.

Telescoping linear actuators for space-constrained applications

Rollon's new TLS telescoping linear actuators enable long stroke lengths with minimal closed lengths, which is especially good for applications with minimal vertical clearance. These actuators integrate seamlessly into multi-axis systems and are available in two- or three-stage versions. Equipped with a built-in automated lubrication system, the TLS Series features a synchronized drive system, requiring only a single motor to achieve motion. Four sizes (100, 230, 280, and 360) with up to 3,000-mm stroke length.

Rollon's new TLS telescoping linear actuators enable long stroke lengths with minimal closed lengths, which is especially good for applications with minimal vertical clearance. These actuators integrate seamlessly into multi-axis systems and are available in two- or three-stage versions. Equipped with a built-in automated lubrication system, the TLS Series features a synchronized drive system, requiring only a single motor to achieve motion. Four sizes (100, 230, 280, and 360) with up to 3,000-mm stroke length.

Learn more.

Competitively priced long-stroke parallel gripper

The DHPL from Festo is a new generation of pneumatic long-stroke grippers that offers a host of advantages for high-load and high-torque applications. It is interchangeable with competitive long-stroke grippers and provides the added benefits of lighter weight, higher precision, and no maintenance. It is ideal for gripping larger items, including stacking boxes, gripping shaped parts, and keeping bags open. It has high repetition accuracy due to three rugged guide rods and a rack-and-pinion design.

The DHPL from Festo is a new generation of pneumatic long-stroke grippers that offers a host of advantages for high-load and high-torque applications. It is interchangeable with competitive long-stroke grippers and provides the added benefits of lighter weight, higher precision, and no maintenance. It is ideal for gripping larger items, including stacking boxes, gripping shaped parts, and keeping bags open. It has high repetition accuracy due to three rugged guide rods and a rack-and-pinion design.

Learn more.

Extend your range of motion: Controllers for mini motors

FAULHABER has added another extremely compact Motion Controller without housing to its product range. The new MC3603 controller is ideal for integration in equipment manufacturing and medical tech applications. With 36 V and 3 A (peak current 9 A), it covers the power range up to 100 W and is suitable for DC motors with encoder, brushless drives, or linear motors.

FAULHABER has added another extremely compact Motion Controller without housing to its product range. The new MC3603 controller is ideal for integration in equipment manufacturing and medical tech applications. With 36 V and 3 A (peak current 9 A), it covers the power range up to 100 W and is suitable for DC motors with encoder, brushless drives, or linear motors.

Learn more.

When is a frameless brushless DC motor the right choice?

Frameless BLDC motors fit easily into small, compact machines that require high precision, high torque, and high efficiency, such as robotic applications where a mix of low weight and inertia is critical. Learn from the experts at SDP/SI how these motors can replace heavier, less efficient hydraulic components by decreasing operating and maintenance costs. These motors are also more environmentally friendly than others.

Frameless BLDC motors fit easily into small, compact machines that require high precision, high torque, and high efficiency, such as robotic applications where a mix of low weight and inertia is critical. Learn from the experts at SDP/SI how these motors can replace heavier, less efficient hydraulic components by decreasing operating and maintenance costs. These motors are also more environmentally friendly than others.

View the video.

Tiny and smart: Step motor with closed-loop control

Nanotec's new PD1-C step motor features an integrated controller and absolute encoder with closed-loop control. With a flange size of merely 28 mm (NEMA 11), this compact motor reaches a max holding torque of 18 Ncm and a peak current of 3 A. Three motor versions are available: IP20 protection, IP65 protection, and a motor with open housing that can be modified with custom connectors. Ideal for applications with space constraints, effectively reducing both wiring complexity and installation costs.

Nanotec's new PD1-C step motor features an integrated controller and absolute encoder with closed-loop control. With a flange size of merely 28 mm (NEMA 11), this compact motor reaches a max holding torque of 18 Ncm and a peak current of 3 A. Three motor versions are available: IP20 protection, IP65 protection, and a motor with open housing that can be modified with custom connectors. Ideal for applications with space constraints, effectively reducing both wiring complexity and installation costs.

Learn more.

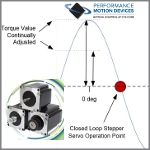

Closed loop steppers drive new motion control applications

According to the motion experts at Performance Motion Devices, when it comes to step motors, the drive technique called closed loop stepper is making everything old new again and driving a burst of interest in the use of two-phase step motors. It's "winning back machine designers who may have relegated step motors to the category of low cost but low performance."

According to the motion experts at Performance Motion Devices, when it comes to step motors, the drive technique called closed loop stepper is making everything old new again and driving a burst of interest in the use of two-phase step motors. It's "winning back machine designers who may have relegated step motors to the category of low cost but low performance."

Read this informative Performance Motion Devices article.

Intelligent compact drives with extended fieldbus options

The intelligent PD6 compact drives from Nanotec are now available with Profinet and EtherNet/IP. They combine motor, controller, and encoder in a space-saving package. With its 80-mm flange and a rated power of 942 W, the PD6-EB is the most powerful brushless DC motor of this product family. The stepper motor version has an 86-mm flange (NEMA 34) and a holding torque up to 10 Nm. Features include acceleration feed forward and jerk-limited ramps. Reduced installation time and wiring make the PD6 series a highly profitable choice for machine tools, packaging machines, or conveyor belts.

The intelligent PD6 compact drives from Nanotec are now available with Profinet and EtherNet/IP. They combine motor, controller, and encoder in a space-saving package. With its 80-mm flange and a rated power of 942 W, the PD6-EB is the most powerful brushless DC motor of this product family. The stepper motor version has an 86-mm flange (NEMA 34) and a holding torque up to 10 Nm. Features include acceleration feed forward and jerk-limited ramps. Reduced installation time and wiring make the PD6 series a highly profitable choice for machine tools, packaging machines, or conveyor belts.

Learn more.

Will robots bring a job apocalypse? MIT report examines how to make technology work for society -- big changes ahead

By Peter Dizikes, MIT

Automation is not likely to eliminate millions of jobs any time soon -- but the U.S. still needs vastly improved policies if Americans are to build better careers and share prosperity as technological changes occur, according to a new MIT report about the workplace.

The report, which represents the initial findings of MIT's Task Force on the Work of the Future, punctures some conventional wisdom and builds a nuanced picture of the evolution of technology and jobs, the subject of much fraught public discussion.

The likelihood of robots, automation, and artificial intelligence (AI) wiping out huge sectors of the workforce in the near future is exaggerated, the task force concludes -- but there is reason for concern about the impact of new technology on the labor market. In recent decades, technology has contributed to the polarization of employment, disproportionately helping high-skilled professionals while reducing opportunities for many other workers, and new technologies could exacerbate this trend.

Moreover, the report emphasizes, at a time of historic income inequality, a critical challenge is not necessarily a lack of jobs, but the low quality of many jobs and the resulting lack of viable careers for many people, particularly workers without college degrees. With this in mind, the work of the future can be shaped beneficially by new policies, renewed support for labor, and reformed institutions, not just new technologies. Broadly, the task force concludes, capitalism in the U.S. must address the interests of workers as well as shareholders.

"At MIT, we are inspired by the idea that technology can be a force for good. But if as a nation we want to make sure that today's new technologies evolve in ways that help build a healthier, more equitable society, we need to move quickly to develop and implement strong, enlightened policy responses," says MIT President L. Rafael Reif, who called for the creation of the Task Force on the Work of the Future in 2017.

"Fortunately, the harsh societal consequences that concern us all are not inevitable," Reif adds. "Technologies embody the values of those who make them, and the policies we build around them can profoundly shape their impact. Whether the outcome is inclusive or exclusive, fair or laissez-faire, is therefore up to all of us. I am deeply grateful to the task force members for their latest findings and their ongoing efforts to pave an upward path."

"There is a lot of alarmist rhetoric about how the robots are coming," adds Elisabeth Beck Reynolds, executive director of the task force, as well as executive director of the MIT Industrial Performance Center. "MIT's job is to cut through some of this hype and bring some perspective to this discussion."

Reynolds also calls the task force's interest in new policy directions "classically American in its willingness to consider innovation and experimentation."

Anxiety and inequality

The core of the task force consists of a group of MIT scholars. Its research has drawn upon new data, expert knowledge of many technology sectors, and a close analysis of both technology-centered firms and economic data spanning the postwar era.

The report addresses several workplace complexities. Unemployment in the U.S. is low, yet workers have considerable anxiety, from multiple sources. One is technology: A 2018 survey by the Pew Research Center found that 65 to 90 percent of respondents in industrialized countries think computers and robots will take over many jobs done by humans, while less than a third think better-paying jobs will result from these technologies.

Another concern for workers is income stagnation: Adjusted for inflation, 92 percent of Americans born in 1940 earned more money than their parents, but only about half of people born in 1980 can say that.

"The persistent growth in the quantity of jobs has not been matched by an equivalent growth in job quality," the task force report states.

Applications of technology have fed inequality in recent decades. High-tech innovations have displaced "middle-skilled" workers who perform routine tasks, from office assistants to assembly-line workers, but these innovations have complemented the activities of many white-collar workers in medicine, science and engineering, finance, and other fields. Technology has also not displaced lower-skilled service workers, leading to a polarized workforce. Higher-skill and lower-skill jobs have grown, middle-skill jobs have shrunk, and increased earnings have been concentrated among white-collar workers.

"Technological advances did deliver productivity growth over the last four decades," the report states. "But productivity growth did not translate into shared prosperity."

Indeed, says David Autor, who is the Ford Professor of Economics at MIT, associate head of MIT's Department of Economics, and a co-chair of the task force, "We think people are pessimistic because they're on to something. Although there's no shortage of jobs, the gains have been so unequally distributed that most people have not benefited much. If the next four decades of automation are going to look like the last four decades, people have reason to worry."

Productive innovations versus "so-so technology"

A big question, then, is what the next decades of automation have in store. As the report explains, some technological innovations are broadly productive, while others are merely "so-so technologies" -- a term coined by economists Daron Acemoglu of MIT and Pascual Restrepo of Boston University to describe technologies that replace workers without markedly improving services or increasing productivity.

For instance, electricity and light bulbs were broadly productive, allowing the expansion of other types of work. But automated technology allowing for self-check-out at pharmacies or supermarkets merely replaces workers without notably increasing efficiency for the customer or productivity.

"That's a strong labor-displacing technology, but it has very modest productivity value," Autor says of these automated systems. "That's a ‘so-so technology.' The digital era has had fabulous technologies for skill complementarity [for white-collar workers], but so-so technologies for everybody else. Not all innovations that raise productivity displace workers, and not all innovations that displace workers do much for productivity."

Several forces have contributed to this skew, according to the report. "Computers and the internet enabled a digitalization of work that made highly educated workers more productive and made less-educated workers easier to replace with machinery," the authors write.

Given the mixed record of the last four decades, does the advent of robotics and AI herald a brighter future, or a darker one? The task force suggests the answer depends on how humans shape that future. New and emerging technologies will raise aggregate economic output and boost wealth, and offer people the potential for higher living standards, better working conditions, greater economic security, and improved health and longevity. But whether society realizes this potential, the report notes, depends critically on the institutions that transform aggregate wealth into greater shared prosperity instead of rising inequality.

One thing the task force does not foresee is a future where human expertise, judgment, and creativity are less essential than they are today.

"Recent history shows that key advances in workplace robotics -- those that radically increase productivity -- depend on breakthroughs in work design that often take years or even decades to achieve," the report states.

As robots gain flexibility and situational adaptability, they will certainly take over a larger set of tasks in warehouses, hospitals, and retail stores -- such as lifting, stocking, transporting, cleaning, as well as awkward physical tasks that require picking, harvesting, stooping, or crouching.

The task force members believe such advances in robotics will displace relatively low-paid human tasks and boost the productivity of workers, whose attention will be freed to focus on higher value-added work. The pace at which these tasks are delegated to machines will be hastened by slowing growth, tight labor markets, and the rapid aging of workforces in most industrialized countries, including the U.S.

And while machine learning -- image classification, real-time analytics, data forecasting, and more -- has improved, it may just alter jobs, not eliminate them: Radiologists do much more than interpret X-rays, for instance. The task force also observes that developers of autonomous vehicles, another hot media topic, have been "ratcheting back" their timelines and ambitions over the last year.

"The recent reset of expectations on driverless cars is a leading indicator for other types of AI-enabled systems as well," says David A. Mindell, co-chair of the task force, professor of aeronautics and astronautics, and the Dibner Professor of the History of Engineering and Manufacturing at MIT. "These technologies hold great promise, but it takes time to understand the optimal combination of people and machines. And the timing of adoption is crucial for understanding the impact on workers."

Policy proposals for the future

Still, if the worst-case scenario of a "job apocalypse" is unlikely, the continued deployment of so-so technologies could make the future of work worse for many people.

If people are worried that technologies could limit opportunity, social mobility, and shared prosperity, the report states, "Economic history confirms that this sentiment is neither ill-informed nor misguided. There is ample reason for concern about whether technological advances will improve or erode employment and earnings prospects for the bulk of the workforce."

At the same time, the task force report finds reason for "tempered optimism," asserting that better policies can significantly improve tomorrow's work.

"Technology is a human product," Mindell says. "We shape technological change through our choices of investments, incentives, cultural values, and political objectives."

To this end, the task force focuses on a few key policy areas. One is renewed investment in postsecondary workforce education outside of the four-year college system -- and not just in the STEM skills (science, technology, engineering, math) but reading, writing, and the "social skills" of teamwork and judgment.

Community colleges are the biggest training providers in the country, with 12 million for-credit and non-credit students, and are a natural location for bolstering workforce education. A wide range of new models for gaining educational credentials is also emerging, the task force notes. The report also emphasizes the value of multiple types of on-the-job training programs for workers.

However, the report cautions, investments in education may be necessary but not sufficient for workers: "Hoping that ‘if we skill them, jobs will come,' is an inadequate foundation for constructing a more productive and economically secure labor market."

More broadly, therefore, the report argues that the interests of capital and labor need to be rebalanced. The U.S., it notes, "is unique among market economies in venerating pure shareholder capitalism," even though workers and communities are business stakeholders too.

View our terms of use and privacy policy